Webinar

Webinar Key Objectives:

- Review the design of Glass Expansion's high-performance Peltier-cooled cyclonic spray chamber (PCC Kit) and Jet Vortex Interface (JVI) for the Agilent® ICP-MS.

- Nebulizer selection and optimal pairing with the PCC Kit and your Agilent® ICP-MS.

- Evaluate washout data collected using a real-world sample containing more than 4 ppm of Boron to compare the washout efficiency at a high-throughput environmental laboratory, resulting in a 61% improvement.

View Webinar, presented by Randy Mercurio:

Ordering Information

| Part Number | Description |

| KT-1212Q | PCC Quartz Spray Chamber for Agilent® 7850, 7900, 8900 with Actuator Mount |

| KT-1116 | PCC Spray Chamber for Agilent® 7850, 7900, 8900 |

| KT-1116Q | PCC Quartz Spray Chamber for Agilent® 7850, 7900, 8900 |

| KT-1116P | PCC PFA Spray Chamber for Agilent® 7850, 7900, 8900 |

| KT-1206 | PCC Spray Chamber for Agilent® 7700, 7800, 8800 |

| KT-1206Q | PCC Quartz Spray Chamber for Agilent® 7700, 7800, 8800 |

| KT-1206P | PCC PFA Spray Chamber for Agilent® 7700, 7800, 8800 |

Product Benefits

Benefits of the PCC Design:

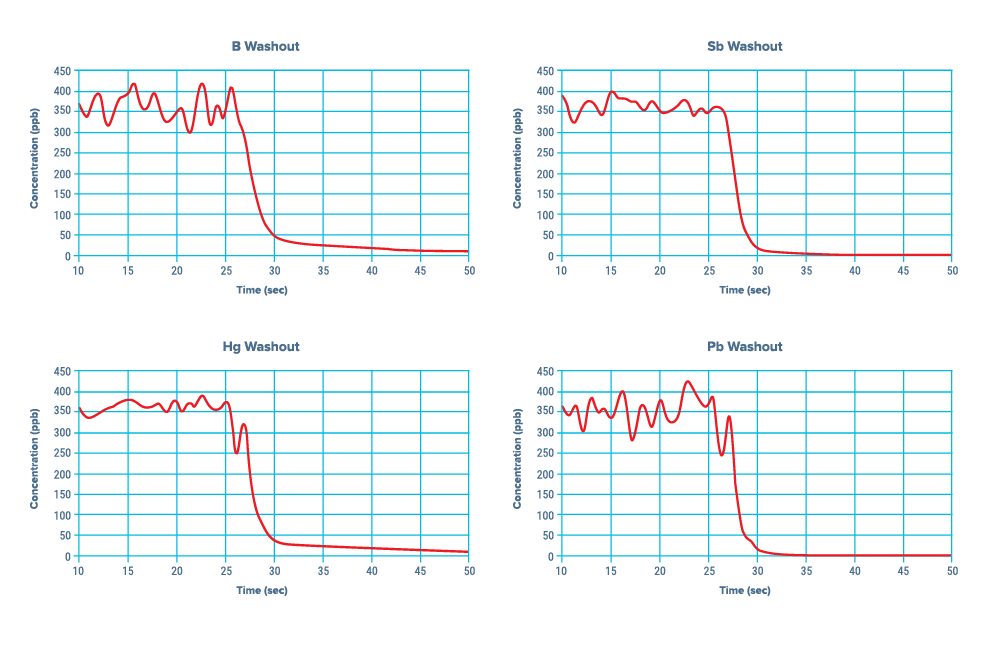

Faster Washout

The unique design of Glass Expansion’s cyclonic spray chamber minimizes washout time with highly concentrated samples and troublesome elements, such as B, Hg, Pb, and Sb, compared to the standard Scott-style spray chamber.

Jet Vortex Interface (JVI™) – Aerosol Filtration

A patent pending, novel design provides highly-efficient Aerosol Filtration. With a simple and straightforward installation, the JVI works in conjunction with the existing "Make-Up" or "Dilution/Option" gas of your ICP-MS.

- Compatible with your existing method settings for HMI and UHMI (7850/7900/8900).

- Chemically inert, made from Teflon® (PTFE).

- Secure connection to gas supply, spray chamber, and transfer tube.

- Improved life of torch & interface cones.

- Reduced build-up on injector & interface cones.

- More robust plasma conditions.

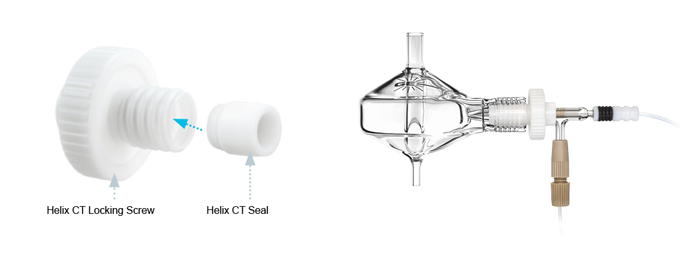

Helix CT Interface

Glass Expansion's cyclonic spray chambers all feature the Helix CT locking screw, which allows for a consistent inert PTFE seal against the nebulizer - making it impossible to overtighten while ensuring a gas-tight seal and optimum nebulizer installation every time.

- A positive stop to ensure that the nebulizer is inserted to the correct and optimum depth within the spray chamber.

- Significantly reduces dead volume around the nebulizer.

- Only nebulizer interface that delivers a ConstantTorque™ seal providing unparalleled, reproducible day-to-day analytical performance.

- Tracey™ design provides the best sensitivity, reproducibility and lowest memory effects.

For more information visit our Helix CT landing page.

Interchangeable Cyclonic Spray Chambers

The PCC Kit provides the ability to easily interchange between glass, quartz, or PFA Helix CT cyclonic spray chambers.

- Glass provides a lower-cost option where low-level Boron measurements are not required.

- High-purity Quartz, the most common option, is required for low-level Boron measurements.

- High-purity PFA, for applications with a hydrofluoric acid matrix and ultra-trace ICP-MS analyses (paired optimally with the OpalMist DC nebulizer).

- The interior of the Tracey PFA spray chamber has the proprietary Stediflow surface treatment, which improves the wettability of the surface and ensures efficient drainage. Without the Stediflow treatment, droplets tend to form on the surface and degrade both sensitivity and precision.

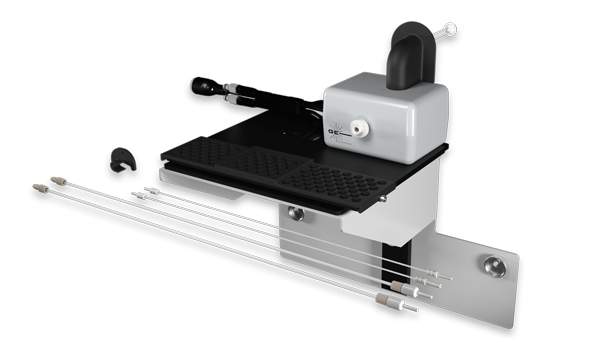

Fast and Simple Installation

The PCC Kit connects directly to the existing electronics and water-cooling system of the Agilent® ICP-MS. A convenient mounting bracket is also included that allows for fast and simple installation on the Agilent® ICP-MS.

Installation Guide

For ICP-MS Semi-Demountable Torch and PCC Kit (KT-1116Q)

This video will provide an installation guide for proper assembly and installation of Glass Expansion's semi-demountable torch and PCC Kit on the Agilent® ICP-MS.

Related Documents

GE Mailing List

Please complete this form to subscribe to the latest Glass Expansion Newsletter.

Thank you

You are now subscribed to the Glass Expansion mailing list.

Customer Comments