Cleaning ICP-MS Cones

When to Clean

The frequency at which the cones are cleaned depends very much on the application and the workload of the instrument. If the samples are clean and the usage is low, the cones may only need cleaning monthly. But if the instrument is in continuous use and/or the samples contain high levels of dissolved solids or are highly corrosive, the cones may need cleaning daily.

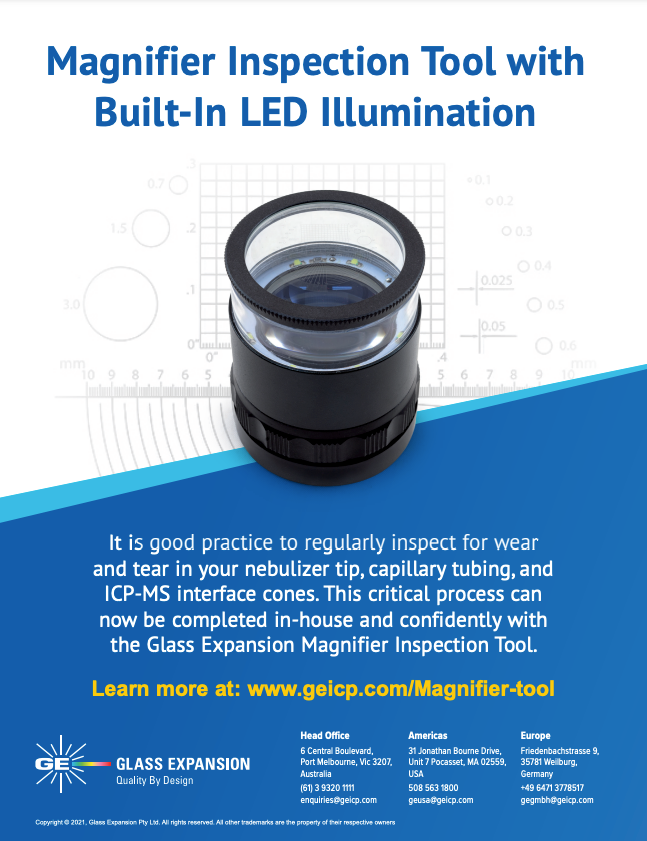

Our Magnifier Inspection Tool (P/N 70-803-1923) is ideal for inspection and measurement of the ICP-MS sampler and skimmer cone orifice. The cones should be cleaned if there are visible deposits near the orifice or if the orifice is blocked or distorted. Deterioration in the performance of the ICP-MS can also indicate that the cones may need cleaning. In particular, watch for increased background signal, memory effects, loss of sensitivity, or distorted peak shapes. A change in the instrument vacuum reading can also be an indication of cone problems. If the orifice gets blocked, the vacuum will increase (pressure decrease), although there will usually be a deterioration in performance before this point. If the vacuum decreases (pressure increases), this could indicate that the orifice is worn and has increased in size. If this happens, the cone needs to be replaced.

The sampler cone, being exposed to the plasma, will usually need cleaning more often than the skimmer cone. If the performance of the instrument does not recover when the cones are cleaned, then you may need to replace them.

What to Use

The method of cleaning will also depend on the application. If the samples are relatively clean, a gentle cleaning process will be sufficient. But if the samples contain high levels of dissolved solids or are highly corrosive, a more aggressive cleaning procedure will be required. A Citranox solution is a gentle and effective cleaning agent, and we recommend that it be tried first. If Citranox is not effective, it may be necessary to use a more aggressive cleaning agent such as nitric acid. However, we recommend that nitric acid not be used unless it is necessary. Nitric acid is more corrosive than Citranox, and prolonged use will reduce the lifetime of the cones. Note that even Citranox will attack copper cones, so the cones should not be exposed to high concentrations of Citranox or exposed for long periods. When cleaning cones which have a screw thread, be particularly careful that the thread is not contacted by nitric acid. Pre-soaking the cones in a detergent such as Fluka RBS-25 before cleaning with Citranox or nitric acid will help the cleaning process. Citranox is manufactured by Alconox Inc. (www.alconox.com), and Fluka RBS-25 by Sigma-Aldrich. Both are available from most suppliers of laboratory chemicals.

How to Clean

Important note:

Always use safety glasses and protective gloves. Be careful when handling the cone – the tip is very easily damaged. Hold the cone by its edge and only use light pressure with your hand when cleaning the tip. Never use tools for cleaning cones.

The cleaning process does not necessarily need to reproduce the original, as-new, polished appearance. Sample deposits need to be removed, but it is not usually a problem if the cone is discoloured. This may result in a more stable signal.

There are three common methods of cleaning cones. From the simplest and gentlest to the most thorough and aggressive, these are:

- Soak the cone overnight in a 25% solution (4x dilution) of Fluka RBS-25.

- Rinse with deionized water.

- Place the cone in a 2% Citranox solution and soak for about 10 minutes.

- Wipe with a soft cloth or Kimwipe dipped in the Citranox solution.

- Wash thoroughly with deionized water.

- Place the cones in deionized water and soak for 2 minutes to remove any residual Citranox.

- Replace the deionized water and repeat the last step at least twice, ie, the cones should be washed in the ultrasonic bath at least 3 times, using fresh deionized water each time.

- Rinse with deionized water and allow to dry or blow-dry with clean argon or nitrogen. Make sure the cones are completely dry. It may help to heat them in a laboratory oven at about 60°C.

- Soak the cone overnight in a 25% solution (4x dilution) of Fluka RBS-25.

- Rinse with deionized water.

- Be very careful to avoid damaging the cone tip. The cone should not be placed in the ultrasonic bath without being supported or contained. One way to avoid damage is to place the cone in a ziplock plastic bag half filled with a 2% Citranox solution and float the bag in the ultrasonic bath. Ensure that the bag is floating so that the cone is not resting on the bottom or touching the walls of the bath. This also minimizes the volume of Citranox used since the bath can be filled with water.

- Sonicate for 5 minutes.

- Wipe with a soft cloth or Kimwipe dipped in the Citranox solution.

- Wash thoroughly with deionized water.

- Replace the Citranox with deionized water and sonicate for 2 minutes to remove any residual Citranox.

- Replace the deionized water and repeat last step at least twice, ie. the cones should be washed in the ultrasonic bath at least 3 times, using fresh deionized water each time.

- Rinse with deionized water and allow to dry or blow-dry with clean argon or nitrogen. Make sure the cones are completely dry. It may help to heat them in a laboratory oven at about 60°C.

- Soak the cone overnight in a 25% solution (4x dilution) of Fluka RBS-25.

- Rinse with deionized water.

- Be very careful to avoid damaging the cone tip. The cone should not be placed in the ultrasonic bath without being supported or contained. One way to avoid damage is to place the cone in a ziplock plastic bag half filled with 5% nitric acid and float the bag in the ultrasonic bath. Ensure that the bag is floating so that the cone is not resting on the bottom or touching the walls of the bath. This also minimizes the volume of nitric acid used since the bath can be filled with water.

- Sonicate for 5 minutes.

- Wipe with a soft cloth.

- Wash thoroughly with deionized water.

- Replace the nitric acid with deionized water and sonicate for 2 minutes to remove any residual nitric acid.

- Replace the deionized water and repeat last step at least twice, ie. the cones should be washed in the ultrasonic bath at least 3 times, using fresh deionized water each time.

- Rinse with deionized water and allow to dry or blow-dry with clean argon or nitrogen. Make sure the cones are completely dry. It may help to heat them in a laboratory oven at about 60°C.

The recommended concentrations of Citranox and nitric acid, and the wash times, should be used as a guide only. Given the wide range of ICP-MS applications, you may need to experiment a little to find the best cleaning procedure for your application. We recommend that you do not use nitric acid any more than is necessary, since it will attack the cone materials. If nitric acid is used excessively, the size of the cone orifice may be increased. If this happens, or if the tip is damaged or deformed, then the cone needs to be replaced.

Cone Conditioning

To ensure the lowest background levels of copper and nickel conditioning cones before use is recommended. A conditioned cone with a uniform coating will also lead to improved long-term stability. Brand-new cones and cones that have gone through cleaning should be conditioned prior to use.

To condition your cones, prepare the following conditioning solutions:

- 1.0% nitric acid blank

- 50ppm calcium in 1.0% nitric acid

Install the new cones or recently cleaned cones into the instrument. Turn on the plasma, and establish robust plasma conditions:

- Aspirate the 50ppm, calcium solution for 10 minutes

- Change to 1.0% nitric acid blank solution and aspirate for a further 10 minutes

Another recommended cone conditioning procedure is to aspirate your highest matrix sample for at least 30 minutes, followed by 10 minutes of aspirating your blank or rinse solution. This method is helpful if your laboratory is analyzing a common matrix each day.

Magnifier Inspection Tool

The condition of your ICP-MS interface cones is critical to analytical performance. Simply use the Magnifier Inspection Tool (P/N 70-803-1923) to check the cone orifice for pitting, matrix build-up, or enlargement at the tip, which can lead to elevated background and poor sensitivity. It’s also a great way to confirm whether your cleaning/maintenance procedures have been successful before reinstalling the interface cones into your ICP-MS.

Platinum Cones

The cleaning procedures outlined above can be used for platinum cones as well as nickel cones. Since platinum is more chemically resistant than nickel, platinum cones can usually be used for longer before they need cleaning. Platinum cones consist of a platinum insert in a nickel or copper base, so aggressive cleaning solutions still need to be avoided as they may attack the base. Platinum cones also run hotter, which helps slow deposition. The lifetime of a platinum cone is typically much longer than that of a nickel cone and can be further extended by refurbishment.

Refurbishment and Reclaim Service for Platinum Cones

Extend the life of your platinum cones with our refurbishment service. Platinum cones have a much longer life than nickel cones but deteriorate over time. In many cases, a platinum cone can be refurbished multiple times, and its lifetime can be greatly extended. As a customer service, Glass Expansion refurbishes platinum cones for a nominal processing fee per cone.

If your platinum cone cannot be refurbished or you have old cones that you would like to reclaim the value for, we will provide a Glass Expansion credit note for the value of the platinum in the cone. There is no limit on the number of cones returned for reclaim, and you can use the full credit value toward purchasing any Glass Expansion products, including new cones.

To take advantage of this program, click here to start an online RMA form for "Pt Cone Refurbish" or "Pt Cone Reclaim." You will need to list your instrument model and the number of platinum sampler and platinum skimmer cones you would like to be evaluated for refurbishing or reclaim.

*Do not ship anything to Glass Expansion until you receive a Return Merchandise Authorization number.

Contact us at enquiries@geicp.com to check the availability of cones for your ICP-MS model.

ConeGuard Thread Protector

When cleaning cones that have a screw thread, it is important that the thread is not contacted by any corrosive solution. If the thread gets corroded, the cone may not seal correctly or it may bond to the base and be difficult to remove. And with Pt cones, the thread is likely to wear out before the Pt insert. The ConeGuard Thread Protector seals the thread and protects it from corrosion during the cleaning process.

Customer Comments