What customers are saying:

"The Eluo worked perfectly."

"I have used it for years. Great tool to have and use regularly to keep your nebulizer clean."

"The TruFlo is a great diagnostic tool."

"The inline filter has reduced the frequency of ICP troubleshooting."

Nebulizer Maintenance Tools

| Part Number | Description |

| 70-ELUO | Eluo Nebulizer Cleaner for Glass concentric Nebulizers |

| 70-ELUO-OPD | Eluo HF Nebulizer Cleaner for OpalMist or DuraMist |

| 70-803-1108 | Guardian in-line sample filter |

| 70-803-1160 | Eluo Adaptor for Inline Filter |

| 70-803-1942 | Guardian in-line Non-Return Gas Filter |

| 70-803-0643 | TruFlo Sample Monitor 0 - 4.0mL/min |

| 70-803-0890 | TruFlo Sample Monitor for HF 0 - 4.0mL/min |

Eluo Nebulizer Cleaner

Previously, there was no simple way to effectively clean and unblock nebulizers. Now, with a revolutionary cleaning tool, the Eluo, blocked nebulizers can be safely and easily restored to optimum performance.

The Eluo is designed to efficiently deliver a cleaning solution through the nebulizer capillary to dislodge particle build-up and thoroughly clean the capillary and gas orifice. One simple action does it all—no more messy procedures or shattered nebulizers in ultrasonic baths.

Use the Eluo regularly to maintain nebulizer performance and prolong nebulizer life.

Recommended Cleaning Procedure:

-

Initially, flush your nebulizer with warm water using the Eluo.

-

Soak the nebulizer tip in a 25% solution of Fluka RBS-25 (Fluka RBS-25 is manufactured by Sigma-Aldrich, and is available from most suppliers of laboratory chemicals) for 24 hours. Use the Eluo to make sure the Fluka solution fills the nebulizer. An initial flush of 25% Fluka using the Eluo may be required.

-

Flush 3 times with warm water using the Eluo.

-

Stubborn deposits may require an additional soaking for 2 hours with nitric acid (5% concentration).

-

Flush 3 times with warm water using the Eluo.

- For faster drying, flush again with methanol.

*Daily cleaning with the Eluo can be done by a quick flush with 25% Fluka, followed by flushing 3 times with warm water and a final flush with methanol for faster drying.

Nebulizer Maintenance Practices to Avoid:

-

Do not insert anything through the orifice of the nebulizer, including wires and probes. This is most likely to damage the nebulizer beyond repair.

-

Never touch the nebulizer tip. Any deposit of body oils can have a detrimental effect on the performance of the nebulizer.

-

Do not use any concentration of HF to clean a glass or quartz nebulizer. Even dilute HF can alter the orifice of the internal capillary and deteriorate the performance of the nebulizer.

-

Do not place a glass nebulizer in an ultrasonic bath as it may dislodge the internal capillary.

- Do not use hot liquid to flush the sample capillary of an inert nebulizer. The temperature can potentially deform the capillary and affect nebulizer performance.

Ordering Information

| Part Number | Description |

| 70-ELUO | Eluo Nebulizer Cleaner for Glass concentric Nebulizers |

| 70-ELUO-OPD | Eluo HF Nebulizer Cleaner for OpalMist or DuraMist |

|

70-0806

|

O-ring Kit for Eluo (2 sets) |

| 70-703-0069 | Eluo Nebulizer Holder for glass concentric nebulizers |

| 70-803-0932 | Eluo HF Nebulizer Holder for OpalMist or DuraMist |

| 70-703-0070 | Eluo Plunger |

| 703-0058 | Eluo Barrel |

Guardian In-Line Particle Filter

Particulates can be found in your samples due to incomplete digestion, contamination from the laboratory environment, or as a precipitate post-digestion. These particulates pose a significant risk for an interruption in production due to a blockage within the capillary tubing, nebulizer, or switching valve. The Guardian In-Line Particle Filter P/N 70-803-1108 provides a simple and effective way to eliminate this risk and significantly reduce the time required to troubleshoot where the blockage is.

This Guardian filter is easily installed on your autosampler probe tubing or sample uptake line to capture and prevent any of these large particulates. The Guardian incorporates a 120 micron filter and is supplied with seals(ferrules) to suit both 1/16 inch (1.6mm) and 1.3mm OD sample tubing.

The purpose-built clog-resistant design is ideal for ICP samples. Any particle build-up is easily removed by back-flushing and ultrasonic cleaning. The PEEK material is suitable for all of the most common ICP solutions.

Back-flushing can be conveniently done using an adaptor connected to the Eluo Nebulizer Cleaning Tool. If you already have the Eluo, you only need to add the adaptor P/N 70-803-1160. If you do not have an Eluo, you will need to purchase the Plunger P/N 70-703-0070 and Barrel P/N 703-0058 or a complete Eluo.

Ordering Information

| Part Number | Description |

| 70-803-1108 | Guardian in-line sample filter |

| 70-803-1160 | Eluo Adaptor for Inline Filter |

|

70-703-0070

|

Eluo Plunger |

| 703-0058 | Eluo Barrel |

|

70-803-0749

|

Replacement Ferrules 1/16 (PKT. 10) |

|

70-803-0748

|

Replacement Ferrules 1.3mm (PKT. 10) |

| 70-803-1350 | Replacement Ratchet Connector |

Guardian In-Line Non-Return Gas Filter

The Guardian DC In-line Non-Return Gas Filter P/N 70-803-1942 from Glass Expansion provides protection for your ICP system in two ways:

- A non-return valve prevents acidified sample or rinse solution syphoning into the instrument gas box.

- 30-micron PolyComb filter protects the nebulizer from particulates in the instrument gas supply.

The Guardian In-line Non-Return Gas is positioned between the Ar inlet on the Direct Connection nebulizer and the gas supply fitting on the instrument. The In-line Non-Return Filter has a one-way valve that allows argon to flow from the instrument into the nebulizer, but prevents liquid syphoning into the instrument. A unique PolyComb 30-micron filter design protects the nebulizer from particulates from the gas supply or from worn or damaged fittings in the gas lines. Unlike Sintered or Frit style filters, the linear honeycomb structure makes PolyComb most resistant to particulate and dissolved solid clogging.

Syphoning of the sample or rinse solution into the nebulizer argon control module on your ICP can occur at the end of an analytic run when the nebulizer gas pressure is turned off and there is liquid in the sample flow path. It is made worse if the autosampler probe stays in the rinse position at the end of a run.

A real problem using an autosampler for unattended overnight runs, it is a silent, invisible killer of your ICP. Acidified solution in the instrument Ar control module can cause corrosion to electronic sensors in mass flow controllers and damage regulators that can result in expensive repairs to your ICP and un-planned down time.

Ordering Information

| Part Number | Description |

| 70-803-1942 | Guardian DC in-line non-return gas filter |

* Requires a DC Gas Line to directly connect to your ICP nebulizer gas supply. If you do not currently use a Glass Expansion DC style nebulizer, click here for a complete list of available DC Gas Lines.

For a universal connection assembly, you will also need to purchase P/N EL-1 (x2), 70-803-1504, and 70-803-1105.

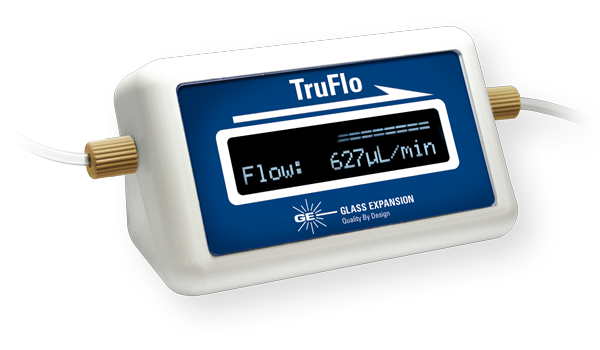

TruFlo Sample Monitor

With the digital display of the TruFlo Sample Monitor, you always know the actual rate of sample uptake to your nebulizer. This enhances the day-to-day reproducibility of your results and reduces the need to repeat measurements due to a blocked nebulizer, worn pump tubing or incorrect clamping of the pump tube.

- Eliminates guesswork

- Sounds an out-of-range alarm

- Reduces sample repeats

- Ideal for sample introduction by peristaltic pump or natural aspiration

- Suitable for all ICP-OES and ICP-MS models

The TruFlo is a precision device that incorporates an accurate flow sensor to facilitate real-time measurement of low liquid flow rates. The inert flow path comprises PEEK, borosilicate glass and Teflon, making it suitable for use with most liquids. The flow rate can be logged by your computer and displayed on the built-in screen. We can even customize the output to fit your requirements.

Ordering Information

| Part Number | Description |

| 70-803-0643 | TruFlo Sample Monitor 0 - 4.0mL/min |

| 70-803-0774 | TruFlo Sample Monitor 0 - 0.05mL/min |

| 70-803-0788 | TruFlo Sample Monitor 0 - 1.0mL/min |

| 70-803-0890 | TruFlo Sample Monitor for HF 0 - 4.0mL/min |

| 70-803-0892 | TruFlo Sample Monitor for HF 0 - 0.05mL/min |

| 70-803-0891 | TruFlo Sample Monitor for HF 0 - 1.0mL/min |

QA Kit

Looking for the complete QC package to ensure optimum performance, day-to-consistency, and long-life of your nebulizer investment? The answer to this is quite simple, our QA Kit is a convenient package combining the TruFlo Sample Monitor, Inline Particle Filter, Eluo Nebulizer Cleaning Tool and Eluo Adaptor for Inline Filter. The QA Kit enhances the reproducibility of your results, greatly reduces the chance of a blocked nebulizer, and alerts you when the filter needs to be back-flushed.

Related Documents

GE Mailing List

Please complete this form to subscribe to the latest Glass Expansion Newsletter.

Thank you

You are now subscribed to the Glass Expansion mailing list.

Customer Comments