The spray chamber is a crucial component of the ICP sample introduction system since it has a profound effect on transport efficiency, precision, and washout. Glass Expansion revolutionized the spray chamber design for the ICP industry with the introduction Tracey™ and Twister™ cyclonic spray chambers, providing improved efficiency and reduced washout. Prior to the cyclonic spray chamber, Scott-style spray chambers were the standard option provided with an ICP. The design of Glass Expansion’s cyclonic spray chambers helps the ICP analyst achieve sensitivity gains, reduced washout times, and reduced matrix effects not possible with other designs. In addition, Glass Expansion’s unique Helix CT (ConstantTorque™) nebulizer interface provides a zero dead volume-seal that results in higher throughput and improved performance compared to non-Glass Expansion designs.

In this article, we will compare the washout of a Glass Expansion cyclonic spray chamber with a Helix CT fitting to both a cyclonic spray chamber without the Helix CT, as well as a commercially available Scott-style spray chamber.

Introduction

Certain elements that are of particular importance to cannabis testing, such as Hg, exhibit prolonged residence in the sample introduction region of an ICP-MS and, as a result, necessitate extended washout times or modified rinse reagents. There are several potential causes for this problematic issue, one of which is entirely the result of the spray chamber design.

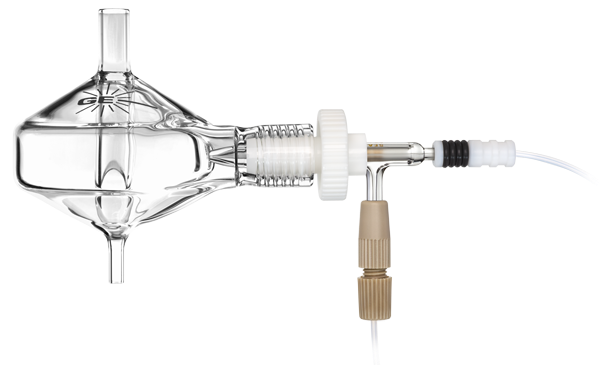

There are two common types of spray chambers used: the Scott type and cyclonic type (Figures 1a and 1b), both of which are available as single-pass or double-pass. In the Scott-type, the sample is injected axially along an inner glass tube and then turns 180 degrees to an outer tube, where it is guided into the torch, allowing gravity to separate the large and small aerosolized droplets. In a cyclonic spray chamber, sample aerosol is injected tangentially, allowing the largest droplets to be flung to the outside of the chamber and drained away. Overall, cyclonic spray chambers have a smaller surface area upon which the aerosolized sample can contact and onto which it can potentially adsorb. The additional unique design features of Glass Expansion’s Twister™ double-pass cyclonic spray chamber are depicted in Figure 1b.

In addition to the design of the spray chamber, the method of securing the nebulizer to the spray chamber is of significant importance for improved washout and decreased memory effects. Most ICP spectrometers rely on an O-ring seal between the nebulizer and the spray chamber. This design may result in extended washout times due to dead volume around the seal. The new Helix CT, now standard on all Glass Expansion cyclonic spray chambers, eliminates dead volume, resulting in faster washout times and higher sample throughput.

The main feature of the Helix CT spray chamber is a new Helix locking screw with built-in torque control mechanism that allows for a consistent seal of the PTFE ferrule against the nebulizer – making it impossible to overtighten or under-tighten while ensuring a gas-tight seal every time. A new PressFit PTFE ferrule provides a chemically inert seal around the nebulizer, which is immune to strong acids and organic solvents routinely used in ICP sample preparation. The new Helix CT cyclonic spray chamber by Glass Expansion, therefore, eliminates all the drawbacks of the O-ring nebulizer seal, while improving user safety by preventing broken nebulizers.

The evolution of Glass Expansion cyclonic spray design, specifically the advantages of the Helix nebulizer-spray chamber interface, was summarized in a 2014 article1. In addition to the Helix interface, the benefits of each Glass Expansion cyclonic spray chamber model are detailed, making it easy for ICP analysts to select the optimum spray chamber to suit their application needs.

Several solutions to the problem of longer washout times (independent of spray chamber design) have been proposed and employed, including extending the duration of solvent rinsing between samples, increasing the acidity of the rinse solution, adding simple rinse matrix modifiers, such as a small amount of Au in the case of Hg carryover, concocting a complex rinse solution, often containing compounds such as ammonia, hydrogen peroxide, EDTA, and or surfactants such as Triton X-100; however, there are possible complications and limitations of such techniques. Extending the duration of solvent rinsing reduces sample throughput and increases solvent consumption. Increasing the acidity of the rinse solution increases the consumption of often expensive trace metal grade acids and can degrade standard peristaltic pump tubing more rapidly, along with the sampler and skimmer cones. Matrix modifiers, such as Au, may be effective for some elements over others, and complex rinse solutions are time-consuming to blend and may contain costly reagents. All of these solutions lead to an increase in the operating cost of an ICP-MS and a decrease in sample throughput. For these reasons, it is imperative to include the design of the spray chamber when considering effective washout procedures.

Results

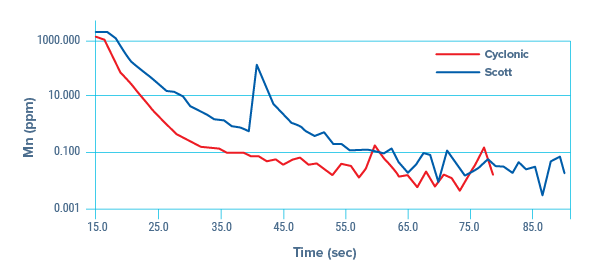

For the Helix CT vs. O-ring washout comparison, an Agilent® 5100 simultaneous dual view ICP-OES was used in combination with the SeaSpray DC nebulizer and Twister cyclonic spray chamber with Helix CT. The Helix CT is the only nebulizer-spray chamber interface that significantly reduces the dead volume around the nebulizer. This unique design minimizes washout time with highly concentrated samples, reducing sample-to-sample carryover and improving sample throughput. Figure 2 compares the time required to wash out a 10 ppm Molybdenum standard with the Helix CT interface and a Brand-X spray chamber with an O-ring interface. The results show that with the Helix nebulizer interface a 10 ppm standard can be washed out in as little as 4 seconds, whereas Brand-X takes 16 seconds. One can expect this time to significantly increase for more troublesome or sticky elements that are more prone to carryover issues.

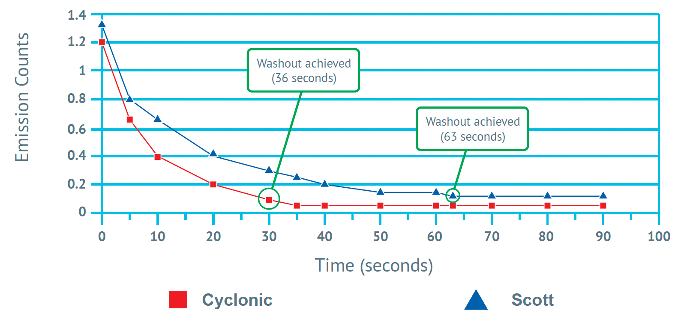

For the cyclonic vs. Scott washout comparison, a Shimadzu® ICPMS-2030 was used in combination with a MicroMist DC nebulizer and both a Twister cyclonic spray chamber and a Brand-X double-pass Scott spray chamber to acquire time-resolved data for a 100 ppb solution of Hg preserved in 2% HNO3. The results in Figure 3 show that the design of the cyclonic spray chamber results in a 43% faster washout time using a standard 1% HNO3 rinse solution (with 1 ppm Au). For a 100 ppb Hg solution, the washout time for the cyclonic spray chamber was 36 seconds, whereas the washout time for the Scott-style spray chamber was 63 seconds.

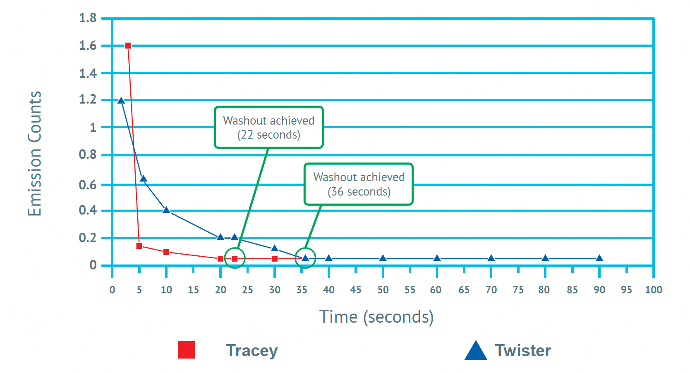

In addition to this comparison, the washout time of a Glass Expansion Tracey spray chamber (single-pass) was compared to the same Twister spray chamber (double-pass). The results in Figure 4 show that the washout time is 39% faster utilizing a single-pass cyclonic spray chamber. For a 100 ppb Hg solution, the washout time for the Tracey was 22 seconds, whereas the washout time for the Twister was 36 seconds.

Conclusions

The results from our study show how the design of both the spray chamber and the nebulizer fitting can have dramatic effects on washout. The Helix CT study shows that the dead volume around the interface can have negative consequences in terms of washout, with results indicating a 4x improvement in washout times when utilizing the zero-dead-volume Helix CT fitting from Glass Expansion. The cyclonic/Scott study shows that all other parameters remain the same, a cyclonic spray chamber will have a nearly 2x improvement in washout as compared to the older Scott-style spray chamber.

References

- Glass Expansion Newsletter, October 2014 Issue, ICP Spray Chamber Update.

- Glass Expansion Newsletter, February 2018 Issue, Helix

CT ICP Spray Chamber with ConstantTorque Technology

Provides Consistent Day-to-Day Analytical Performance.