The Role of the RF Coil

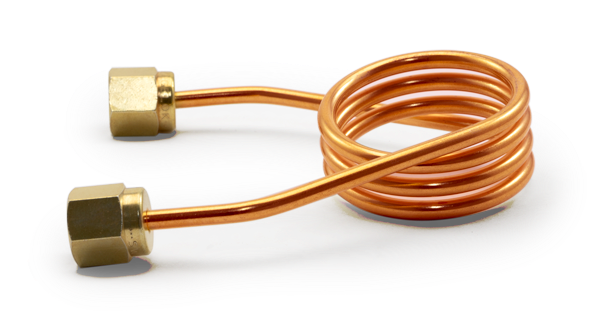

The RF coil is the last component in the electrical system used to generate an Argon plasma. Being the last component, there is great importance placed on the coil for transferring RF energy to the plasma.

- Concentricity and alignment are very important in producing a correctly shaped plasma, which consistently needs to be located in the same position.

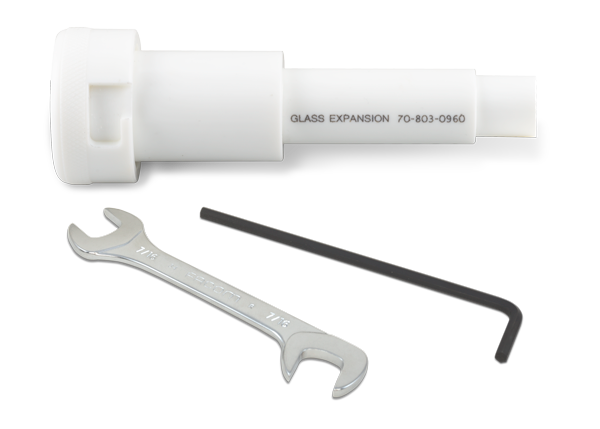

- The Glass Expansion RF Coil installation tools with plastic coil supports make this possible every time.

- Correct dimensions - being part of the RF system, the coil dimensions are also important in the tuning of the circuit. Slight changes in dimensions can produce small changes in resistance or inductance and are normally compensated for in the tuning circuitry of the system.

- Base metal/plating - the most efficient conductor of RF energy is pure silver followed by annealed copper. There is very little difference in the conductivity of these materials but there is a great deal of difference in cost. Copper is used as the base material of all commercially available coils but different manufacturers use different plating materials. Silver has the best conductance and gold has the best corrosion resistance.

Being exposed to the environment of the torch box, the condition of the coil has a major effect on the efficiency of transferring energy to the plasma. The greater the corrosion, the larger the electrical energy that is required to produce a plasma of the same power. This transfers undue stress on the rest of the electrical components used in the RF system, possibly contributing to premature failure.

- Argon gas flow rates and quality.

- The torch contains the plasma. The torch needs to be concentric and of the highest quality Quartz. If the outer tube becomes devitrified, the transfer of energy is restricted due to losses incurred by heating on the surface of the outer tube, thereby reducing the available energy for the atoms.

- The RF generating system, including the coil. All RF systems available in commercial ICP instruments are capable of supplying the required power. The one component that is common to all instruments is the coil. Each instrument has a different type of coil, with different dimensions and different numbers of turns.

RF coils are one of a number of critical components needed to produce plasma. With the Glass Expansion RF coils and installation tools, it is now possible to replace your coil on a more regular basis without the cost of a service visit. This ensures this part of the RF system continues to work in peak condition.

- Regular replacement of corroded coils reduces the load on the RF generating system

- Changing corroded coils increases energy transfer, resulting in a more robust plasma and generally higher analytical line intensities

PRODUCT BENEFITS

Advantages of Glass Expansion RF Coils

- High-quality and consistent plating of our coils promotes extended coil life

- Each coil is supplied on a plastic former ensuring correct dimensions and easier installation

- Each coil is supplied in a special protective container to ensure correct dimensions are maintained, and the coil arrives corrosion-free

- Correct alignment of the coil with respect to the torch body reduces devitrification of the outer tube

- Reusable alignment tools ensure correct installation every time. Our CD with Do-It-Yourself instructions saves time

Corrosion Resistance

From a conductivity point, the best material to make a coil from would be pure silver, but, due to the high cost, this is impractical. Copper is the next best material, but the copper must be of an acceptable grade and contain a minimum of contaminants. The copper used by Glass Expansion has a purity of 99.9% minimum. Once the base material is fixed, the environmental conditions under which the coil is placed need to be considered. The environmental conditions in the torch box include corrosive gases and high temperatures. These vary with instruments and plasma orientation (Radial or Axial). This leads to the use of plating of the copper coils to help prevent unwanted corrosion, with the two most common materials being Silver and Gold. The plating process is vital to the conductivity of the coil. Many different types of plating procedures result in varying degrees of conductivity. The procedure used by Glass Expansion does not use additive brighteners or corrosion inhibitors in the plating bath. This produces a dull coating, which is then manually polished to give a final bright appearance, resulting in a coil that retains the highest possible IACS rating.

Coils should be continually cleaned to remove the build-up of surface oxidation. The rate of corrosion is higher for Copper, followed by Silver, then Gold. There are, however, distinct advantages to using Silver. The plating process for Silver leaves a more even surface allowing fewer sites for the chemical attack. The conductivity of Silver is much higher than that of Gold, but Gold does offer greater protection in more aggressive environments.

Glass Expansion recommends coils in Silver and Gold due to better conductivity and corrosion resistance.

- There are fewer problems with a silver-plated coil with arcing between windings, compared to the standard copper coil. This in turn, lengthens the life of the coil.

- Another advantage is our installation guide and alignment tools. These allow Do-It-Yourself installations, saving the expense of a service engineer. These installation guides, written on Compact Discs, will show you how to set up and align your torch and coil to the exact specifications. This reduces torch wear due to misaligned coils, especially in axial systems.

- All coils produced by Glass Expansion will be shipped with a coil former. This former holds the coil in the correct dimensions during shipping and installation.

- The tool can also be used to check the dimensions from time to time or to reset after an accidental knock.

- The packaging of Glass Expansion's coils will ensure that the coil arrives at the customer's site in the correct dimensions.

Plasma Generation

The generation of a plasma is the result of a complex RF circuit design. Many of the environmental problems that affect the coil have little effect on the operation of the RF generator, except that corrosion produces an added load. In particular, corrosion of the coil has a significant effect on the performance and robustness of the plasma. Changing to a new coil reduces the load on the RF generator since the current required to produce the same level of power is reduced as the resistance of the coil is reduced. Hence, having a coil with little or no corrosion has a positive effect on the longevity of the PA (Power Amplifier) Tube or RF FET (Field Effect Transistor) due to the lower current required.

Conductivity

This can be explained by the conductivity of pure metals and oxides. Pure grade copper has an IACS (International Annealed Copper Standard) of 100, silver has an IACS of 105, and Gold has an IACS of 74. In referencing the ICAS system, a higher IACS indicates higher conductivity. The following websites contain information on the IACS for various metals www.eddy-current.com/

The formation of an oxide on the surface of the coil reduces the conductivity of the coil and hence its performance. Depending on the instrument and the control feedback system, this can be seen by a reduction in the intensity of an element of the same concentration over the life of the coil.

Ordering Information

RF Coils are currently available for the following models:

| Manufacturer | Model |

| Agilent Technologies® | 5100,5110,5800,5900 |

| Agilent Technologies ® (Varian) | 700-ES Series Axial, Vista Axial |

| Agilent Technologies® (Varian) | 700-ES Series Radial, Vista Radial, Liberty 100/120/150/200/220 |

| Agilent Technologies® (HP) | 7700, 8800, 8900 |

| Agilent Technologies® (HP) | 7800, 7900 |

| Horiba® | 24, 38 & 138 Series, Ultima, Activa |

| PerkinElmer® | Optima 2000,4000,5000,7000 DV Series |

| PerkinElmer® | Optima 4300V, 5300V, 7300V |

| PerkinElmer® | NexION 300, 350 |

| Shimadzu® | 7000, 8000, 9000, 9800 Series |

| Shimadzu® | ICPM-8500, ICPMS-2030 |

| Thermo Scientific™ | PRO DUO |

| Thermo Scientific™ | PRO Radial |

| Thermo Scientific™ | 6000, 7000 Duo |

| Thermo Scientific™ | 6000, 7000 Radial |

RF Coil Installation Kits

Save the cost of a service call

The Glass Expansion RF Coil Installation tool helps with the correct alignment of the RF coil with respect to the torch body which reduces devitrification on the outer tube. The alignment tool is re-useable to ensure the correct installation of the coil every time.

All tools in the RF Coil Installation Kit are designed for each instrument. The tool is designed to align the coil to the torch mounting bracket. All kits come with DIY instructions and help minimize ICP downtime.

- An Installation Tool

- Required Spanner/s

- Instructional USB

Customer Comments